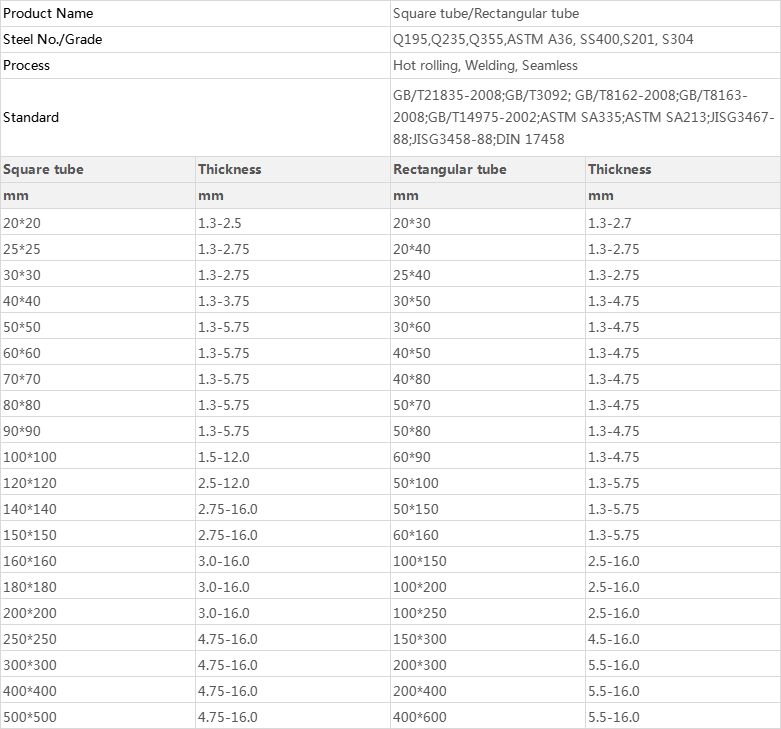

Specification:

Steel pipes have a hollow cross-section, and their length is much greater than the diameter or circumference of the steel. Divided into circular, square, rectangular, and irregular steel pipes according to their cross-sectional shape; Divided by material into carbon structural steel pipes, low-alloy structural steel pipes, alloy steel pipes, and composite steel pipes; Divided by purpose into steel pipes for transportation pipelines, engineering structures, thermal equipment, petrochemical industry, machinery manufacturing, geological drilling, high-pressure equipment, etc; According to the production process, seamless steel pipes are divided into seamless steel pipes and welded steel pipes. Seamless steel pipes are further divided into hot-rolled and cold-rolled (drawn) types, while welded steel pipes are further divided into straight seam welded steel pipes and spiral seam welded steel pipes.

Steel pipes are not only used for transporting fluids and powdery solids, exchanging heat energy, manufacturing mechanical parts and containers, but also an economical steel material. Using steel pipes to manufacture building structural grids, pillars, and mechanical supports can reduce weight, save metal by 20-40%, and achieve factory mechanized construction. Using steel pipes to manufacture highway bridges not only saves steel and simplifies construction, but also greatly reduces the area of protective coating, saving investment and maintenance costs.

|